Stable CHO cell pool and cell line development

However, developing a stable cell line can be a time and resource intensive process with several bottlenecks that need to be overcome in order to ensure a good yield output.

After years of optimization work to counteract these bottlenecks, InVivo successfully established a proprietary platform for the development of stable cell lines using CHO (Chinese hamster ovary) cells as expression system.

Production from stable cell pools

Further examples for when to consider a stable cell pool

Rescue a poorly performing hybridoma cell line

When you use monoclonal antibodies from hybridoma cell lines that do not promise the expected yields, then this does not have to be the end of your project. Some hybridoma lines simply do not show the desired productivity or maybe loose it over time. In such cases, it is beneficial to switch to a recombinant approach and produce the antibody of interest in stable CHO cell pools.

First, we in order to generate the relevant constructs for stable expression in CHO cells. Within just a few weeks, you receive the first samples of your recombinant antibody for testing.

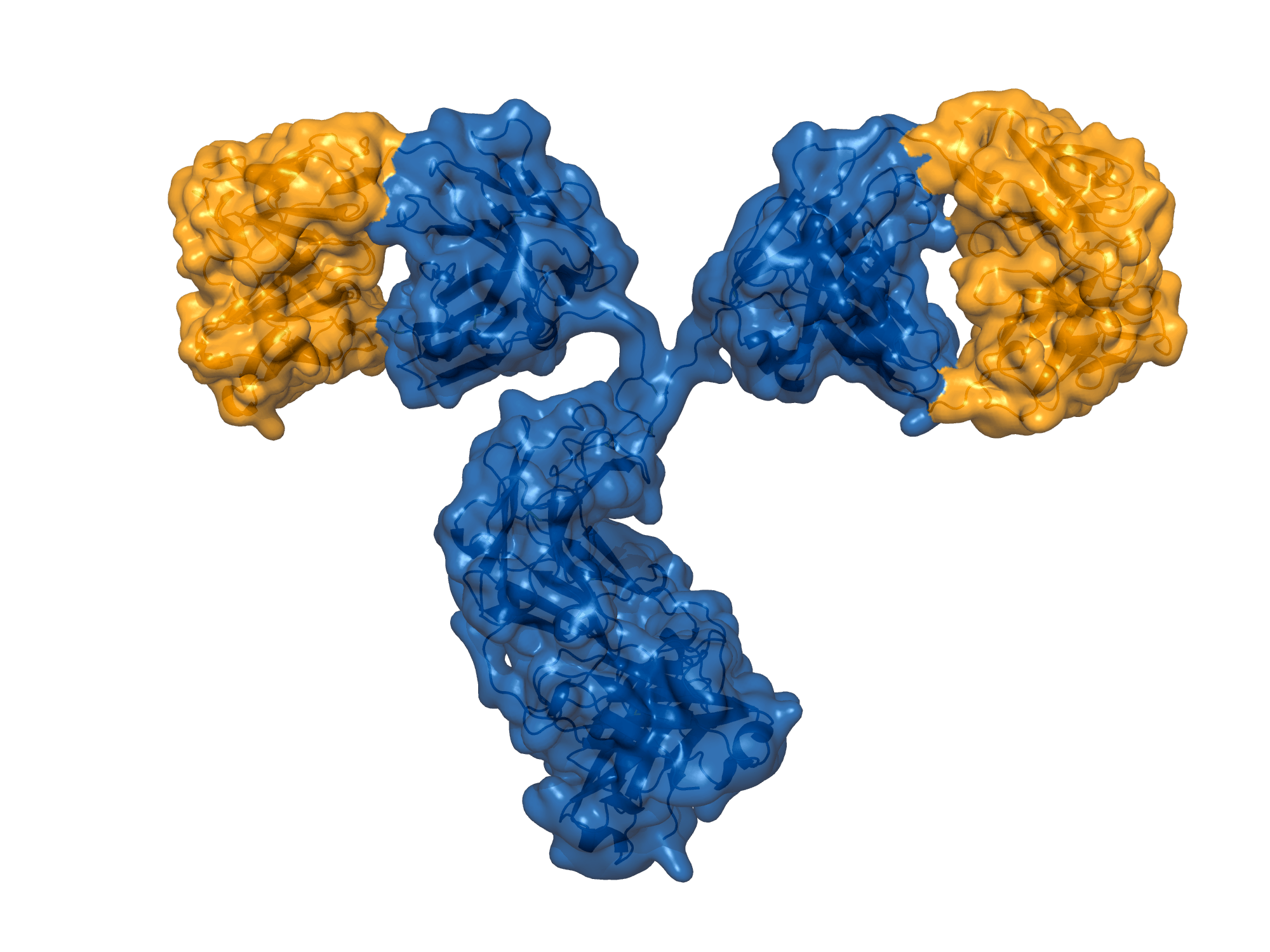

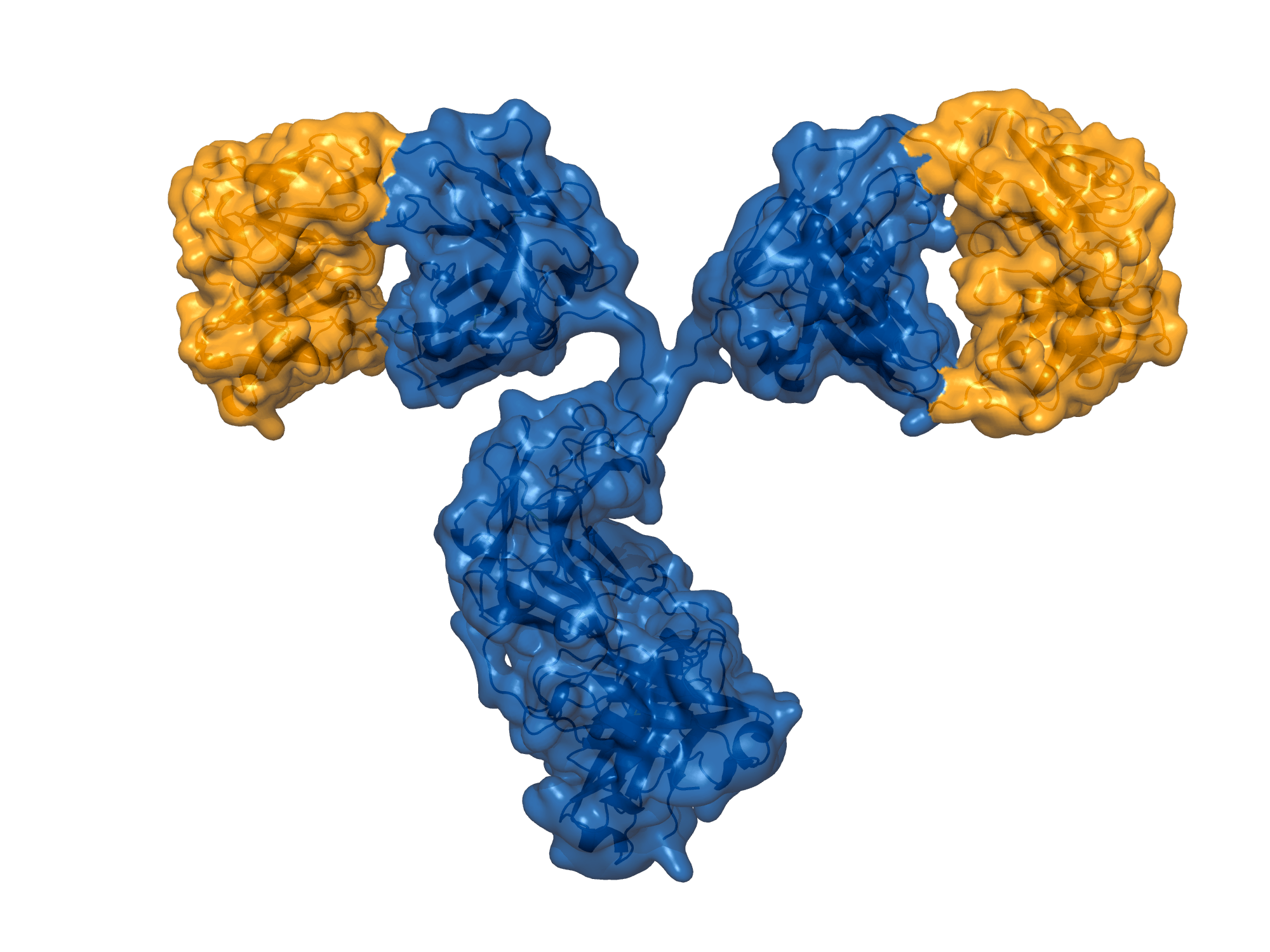

Antibody engineering

Antibody engineering is a fantastic method to optimize antibodies and specifically tailor them for research and downstream applications. Besides sequence optimizations, which potentially lead to higher product yields or higher antibody specificity, also antibody subclass switches can easily be performed as well as generation of chimeric, humanized antibodies. To obtain these custom modified antibodies in large quantities and quick turnaround times, production in stable CHO cells is ideal and highly recommended.

Biopharmaceutical development

The development of biopharmaceuticals is very costly and production capacity in GMP facilities is often limited. To circumvent this problem and speed up research and development, a large part of the pre-clinical studies can be carried out using InVivo’s CHO cell pool concept based on a well-established cGMP-banked cell line, which can later be transferred into GMP facilities.

By using material from stable cell pools to characterize and evaluate potential drug candidates, it is possible to further reduce timeline and costs whilst optimizing the opportunity to process several of such potential targets in parallel.

Workflow

Stable Cell Line Development

Stable Cell Development

DNA-design and cloning

Based on customer reference sequence, the target DNA is designed, optimized and synthesized, followed by cloning into InVivo’s proprietary expression vector. DNA preparation occurs using a sustainable and optimized in-house process to win excellent transfection grade plasmid DNA.

3-4 weeks

PEI-mediated transfection

The expression vector is introduced into CHO cells via PEI-mediated transfection. Through transposon-mediated active gene transfer, the target DNA is stably inserted in the host cell genome.

~ 1 week

Selection of stable expressors

To select for pools with stable expression of the target DNA, double selection with puromycin and MTX is performed. The pools with best productivity are chosen and secured.

4-5 weeks

Selection of best pool

Small-scale test productions with the generated cell pools are performed. Productivity is determined by analytical chromatography, and the best producing cell pool is identified.

2-3 weeks

Single Cell Cloning

The selected cell pool is used for limited dilution to isolate monoclones. Clonality screening occurs with the NyONE FL10 imager; productivity is measured by analytical biolayer interferometry (Octet) and chromatography. Up to 3 monoclones are selected and expanded.

12 weeks

Upscaling production

The best producing cell pool is used for upscaling productions dependent on customer requirements (fed-batch shaker assay or fed-batch fermentation in bioreactor).

5-8 weeks

Clone stability testing

The selected clone is cultivated over 60-70 population doublings and the clone expression stability is evaluated by analytical chromatography

10-12 weeks

Upscaling production

The best monoclone is used for upscaling productions dependent on customer requirements (fed-batch shaker assay or fed-batch fermentation in bioreactor).

5-8 weeks

Production from stable cell lines

Benefits

Cost efficient

InVivo’s highly optimized platform is based on proprietary expression vectors, high quality medium and perfectly harmonized processes. This ensures cost-efficient production with highest product yields at reduced processing times.

Highest flexibility

Every project is unique. Therefore, we offer maximum flexibility when it comes to project design, production scale and product specifications. So, at the end, you get exactly what you need.

Quality assurance

We are ISO9001 and ISO13485 certified and our aim is to achieve excellent quality for all products manufactured at InVivo – every single time with highest purity and perfect batch-to-batch consistency.

Confidentiality

We ensure fully confidential data protection for every project. The intellectual property of the final product lies with you and only you decide if, when and who else gets to access it.

Joint decisions

We guarantee regular project updates and include you into all important decisions along the entire development cascade. Test samples of your product can be shared with every important milestone that we reach, so that you are able to decide on how to proceed.

License free

At InVivo, we produce under non-GMP conditions, therefore no license fees apply and there are no other hidden costs. We only charge for the service we provide. After a cell line or cell pool has been developed, for all subsequent productions, you only pay for the ordered amount of the final product.

Cost efficient

Cost-efficient production through implemented equipment and well-defined processes.

Customized processes

If desired, we adapt our standard processes to your favored protocol.

Product exclusivity

Only you decide who else gets access to your product.

Expert support

Rely on our longstanding expertise.

Joint decisions

We include you to all important decisions along the entire development process.

License free

No royalties. After completion of cell line development, you only pay for the ordered amount of final product.

Invivo Biotech Services

Neuendorfstr. 24a

16761 Hennigsdorf

Germany